+86-0373-3696559

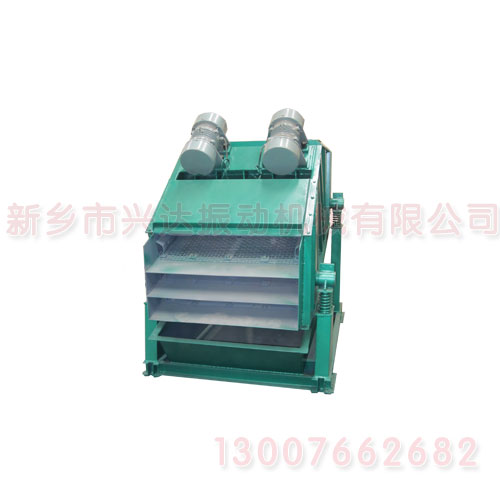

Product Description:linear vibrating screen

Product features:Linear vibrating screen features high screening accuracy, large processing capacity, simple structure, good sealing, convenient maintenance, low energy consumption, small noise, good sealing, dust pollution reduction, long screen life, etc.

Overview

The linear vibrating screen can be used for the automatic operation in the production line. It is applicable to the screening of any dry material with particle size of 0.74-10 mm, water content less than 7%, cohesionless material. It is widely used in the screening of dry powder, fine particle or fine powder materials in the industries of abrasives, chemicals, plastics, medicine, resin powder, ceramic raw materials, metallurgy, building materials, grain, food, fertilizer, etc.

Features

Linear vibrating screen features high screening accuracy, large processing capacity, simple structure, good sealing, convenient maintenance, low energy consumption, small noise, good sealing, dust pollution reduction, long screen life, etc.

Model selection description

Our company can make all kinds of models according to customers' requirements. When selecting and ordering, the screen layer number, screen angle, mesh specification, handling capacity, material name, feed particle size, outlet direction, material, etc. can be indicated.

Use and maintenance

1. When the screen machine is running, its vibration part shall not be connected or contacted with any object outside the machine. (soft connection shall be used under the guidance of the manufacturer);

2. When feeding materials, feed them in the whole width direction of the screen body of the feed inlet to ensure the uniform distribution of materials on the screen surface;

3. When the material falls, there shall be no big impact to avoid damaging the screen;

4. Before starting and stopping the machine, there shall be no materials left on the screen surface;

5. If there is any abnormal sound during the operation of the equipment, it shall be shut down and checked immediately, and it can be started only after troubleshooting;

6. See the operation manual for the maintenance of the vibration motor.